Our versatile and market’s most advanced machinery enables cost-effective and fast service. We manufacture sheet metal products either with a punch, punch-shear or a punch-laser combo-machines. Laser cutting is used for thicker parts. The manufacturing method is selected according to cost-efficiency and customer quality requirements.

Sheet metal punching with automation

We offer sheet metal punching for sheet thicknesses up to 3 mm. We also have punching and shearing combo-machines which reduces production time, especially for large parts. The punch and shear combo-machine first punches and then detaches the part in a continuous process with an integrated shear. Maximum sheet size is 1500 x 4000 mm. Especially in large parts punching and shearing is often the most cost-efficient option for the customer.

Also, forming, marking and tapping are possible with the punching machine. Thanks to a wide range of tools and long-term experience, we are able to manufacture small and large size products quickly and efficiently. We have a total of five sheet metal punching machines in Kauhava and Vaasa.

Machinery:

- 1 x Finn-Power Sharp Genius – punching and laser cutting combo-machine with automatic loading and unloading

- 2 x Finn-Power L+P 6 – punching and laser cutting combo-machine with automatic loading and unloading

- 2 x Finn-Power SG 6 – punching and shearing combo-machine with automatic loading and unloading

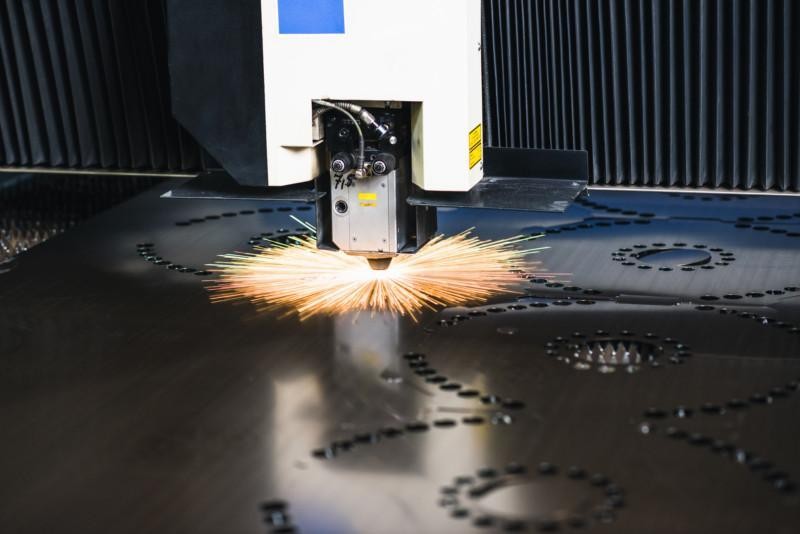

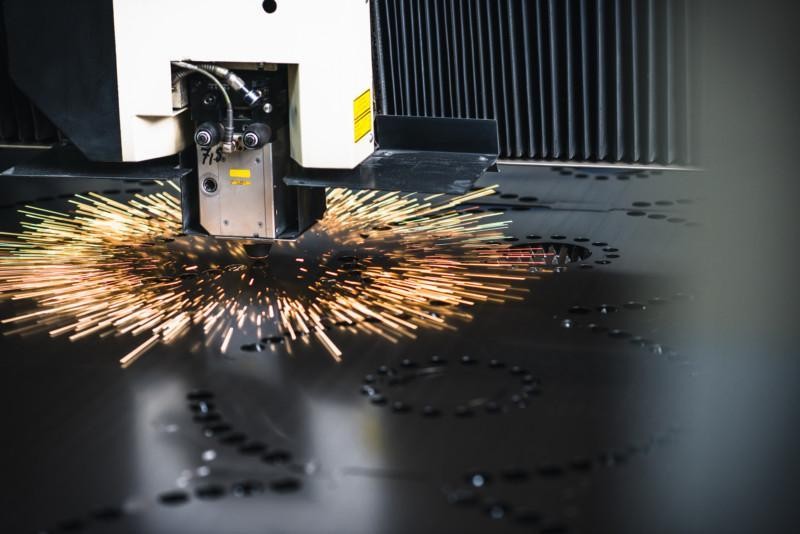

Laser cutting

We have a total of three laser cutting machines in Kauhava and Vaasa. We can process sheet metal with a thickness of up to 25 mm.

Machinery:

- Finn-Power L6 – Laser cutting machine with automatic loading and unloading

- Trumpf 3050 6kW – Laser cutting machine with automatic loading and unloading

- Trumpf TruLaser 5030 Fiber 8kW – Fiber laser cutting machine with automatic loading and unloading

Material storage

- Cold rolled sheets 0,5–3 mm

- Structural steel 3–25 mm

- Galvanized steel 0,5–4 mm

- Stainless steel 0,5–25 mm

- Aluminium (EN AW 1050A) 0,5–3 mm

- Aluminium (EN AW 5754) 0,5–15 mm

- Brass 0,5–3 mm

- Copper 1–10 mm

We are happy to carry out further processing according to your needs.

Check out our other services:

Do you want to know more about us?

Feel free to contact us to discuss or book a meeting!